Pocess Design, Engineering and Management

GEMA PLASTIC Co., Ltd. developed with over 40 years experience in Petrochemical Industry, "GEMATECH" EPS (Expandable Polystyrene) Manufacturing Technology has been implementing for many years in Turkey and global scale and has become an international licensor in this field.

GEMA PLASTIK LTD. STİ. takes into account the customer needs in terms of maximum product quality and environmentally friendly production model and constantly updates its technology by improving equipment, automation design and process optimization.

PROCESS ENGINEERING

GEMA PLASTIK can provide a wide range of process engineering services for the whole project life cycle starting from feasibility study to field supervision. Our strategy is to come along with the best fit solution for the client’s requirements.

We have the flexibility to either provide all process engineering services by our in-house resources or partner up with specialized companies to propose the most optimum solution to the client.

Our multinational team with different levels of experiences including operation, design, and commissioning offers specialized expertise. Besides our references for the execution of large-scale grass-roots projects, one of the strongest sides of the GEMA PLASTIK process group is our proofed experience in providing tailor-made solutions for assessment, debottlenecking and revamping of existing units and/or systems.

PLANT LAYOUT and PIPING

Plant Layout and Piping design is one of the leading services offered by Gema Plastik in the application of "GEMATECH" EPS Raw Material Production Technology. Gema Plastik adheres to customer preferences and local regulations by fully complying with international rules and standards that will be the reference for each project.

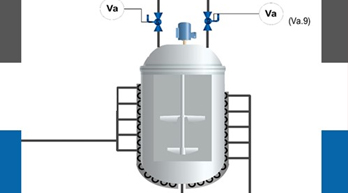

EQUIPMENT DESIGN

Ensuring the safety and reliability of the operation in the field depends on the equipment design. Considering this approach, Gema Plastik provides detailed engineering services in many disciplines including static equipment (pressure vessels, tanks, heat exchangers), rotating equipment (pumps, compressors) and material science within the scope of "GEMATECH" EPS Raw Material Production Technology.

Equipment that will provide high capacity or contain high pressure and temperature in critical services and the like are designed in accordance with international standards, codes and regulations in accordance with customer specifications and operating requirements, with the awareness of safety and reliability.

COATING TECHNOLOGY

One of the most important parameters in the final product quality of Expandable Polystyrene is that the beads are covered with a very thin film with various powder chemicals. A good coating ensures dust-free product and the end user customers can use the product well. Gema Plastik has gained expertise in this field and offers this technology to its customers.

ELECTRICITY

Gema Plastik Elektrik department offers special solutions as stated below in line with the needs and desires of the customer, with the latest technology and developments it follows.

Single Line Schematics, Low Voltage Power Distribution, Medium Voltage Power Distribution, Lightning Protection and Grounding Systems, Cable and Cable Channel Routing, Motor Start-up and Transient Stability Analysis, Lighting Design.

INSTRUMENTATION and SCADA CONTROL

Our Instrumentation and Control Engineering department designs Control Systems and Safety Instrumented Systems (SIS) with the latest technology and developments in accordance with all aspects of the IEC standard and according to the needs and demands of the customer. We offer design engineering solutions ranging from small PLC systems to more complex systems.

DCS / SCADA / SIS applications, control panel design, programming the control system, Control Philosophy and Loop Explanation, Installation Connection Details, Connection Diagrams (Loop, Junction Box), Instrument / Cable / Coil List / Pipe Programs, Material Request, Installation Inspection, Cold and Hot Cycle Control, Functional Control.

BASIC ENGINEERING

Gema Plastik Process and other Engineering disciplines carry out Basic Engineering activities to generate information about basic project requirements in the application of "GEMATECH" EPS Raw Material Technology.

Basic engineering focuses on the design and basic configurations for the entire engineering of the facility and includes:

- Design, engineering philosophies and flow diagrams, single lines etc. for all engineering disciplines such as instrumentation and controls, electrical, piping, rotary and static equipment, mechanical systems. key design outputs such as process and process safety.

- Extended process engineering package with P & IDs, equipment data sheets.

- Plant layout

- Equipment list

- Instrument list

- Process and utility flow diagrams

- Control philosophy

- Fluid list

- Estimated utility consumptions

- Definition of waste water

- The properties of the materials to be used and produced in the process such as raw materials, by-products, products, operating materials and catalysts and the emissions and wastes to be released by the process

- Properties for building materials such as pipe material properties.

DETAILED ENGINEERING

Detailed Engineering is made for the physical realization and commissioning of the EPS Raw Material Plant to be established with "GEMATECH" technology in the field. Almost all details for equipment and supplies are prepared early in this phase. Detay Engineering describes the procurement, fabrication and construction of materials at the highest level of details which are required to ensure that manufacturers and field installation teams progress in their work accurately and efficiently.

Detailed Engineering consists of complex activity groups required to demonstrate the detailed plant setup and to facilitate the facility's material procurement, fabrication, assembly and operation. It consists of calculations, simulations, evaluations, reports, 2D / 3D designs, drawings, data sheets, requests, specifications and material outputs to realize all the concrete requirements of the project to be carried out on site. This engineering phase is the inclusion of the actual data of the materials and equipment supplied for the project in the design to reach the "IFC - Issued For Construction" level of documentation.

PROJECT MANAGEMENT

EPC (Engineering-Procurement-Construction) or Design-Assembly Projects are difficult and every project carries great risks. Customers look for reliable and experienced solution partners while managing projects. Even a delay or error in any of the thousands of different interconnected project tasks causes large project delays and budget overruns. Since financial risk is so high in today's world, every phase of a project must be carefully managed and controlled by experienced and highly skilled professionals.

Gema Plastik helps to reduce customers' risks while applying "GEMATECH" EPS Technology. Our managers review every detail of the projects, plan, set priorities, manage and control every process, determine and solve problems with an analytical method. We offer project management and field management professionals with expertise to suit all customers' needs.