What we do

EPS Raw Material Production Plants & DELION Refinery–Petrochemical Solutions

GEMAGROUP offers turnkey plant solutions for the production of white and graphite/colored EPS raw material (EPS resin)—including process design, engineering, procurement, installation, and commissioning.

In addition, as an authorized representative of DELION, we supply column internals, selected technology and catalysts solutions to refinery and petrochemical plants.

EPS RAW MATERIAL (RESIN) PRODUCTION PLANTS

We build turnkey EPS raw material plants with capacity options tailored to your investment needs—for both white and graphite/colored EPS production. From process design to equipment supply, from installation to commissioning, we manage all steps under one roof.

With over 45 years of petrochemical experience, GEMA PLASTİK LTD. ŞTİ. has been applying its GEMATECH EPS Raw Material Production Technology both in Turkey and globally for many years, and has become an international company in the field of EPS raw material production technologies.

EPS raw material production plants can be built with highly flexible capacities, using reactors ranging from 21 m³ to 50 m³. Thanks to this flexibility, GEMATECH technology offers tailored solutions for a wide range of customer needs—from large-scale industrial production to smaller-scale facilities designed to meet internal demand.

Engineering (process, mechanical, electrical, otomation)

Engineering (process, mechanical, electrical, otomation)- Proprietary equipment and material procurement

- Installation supervision

- Tests, pre-commiioning, commissioning and operation

- Training for engineers and technicians

- Proces optimisation support

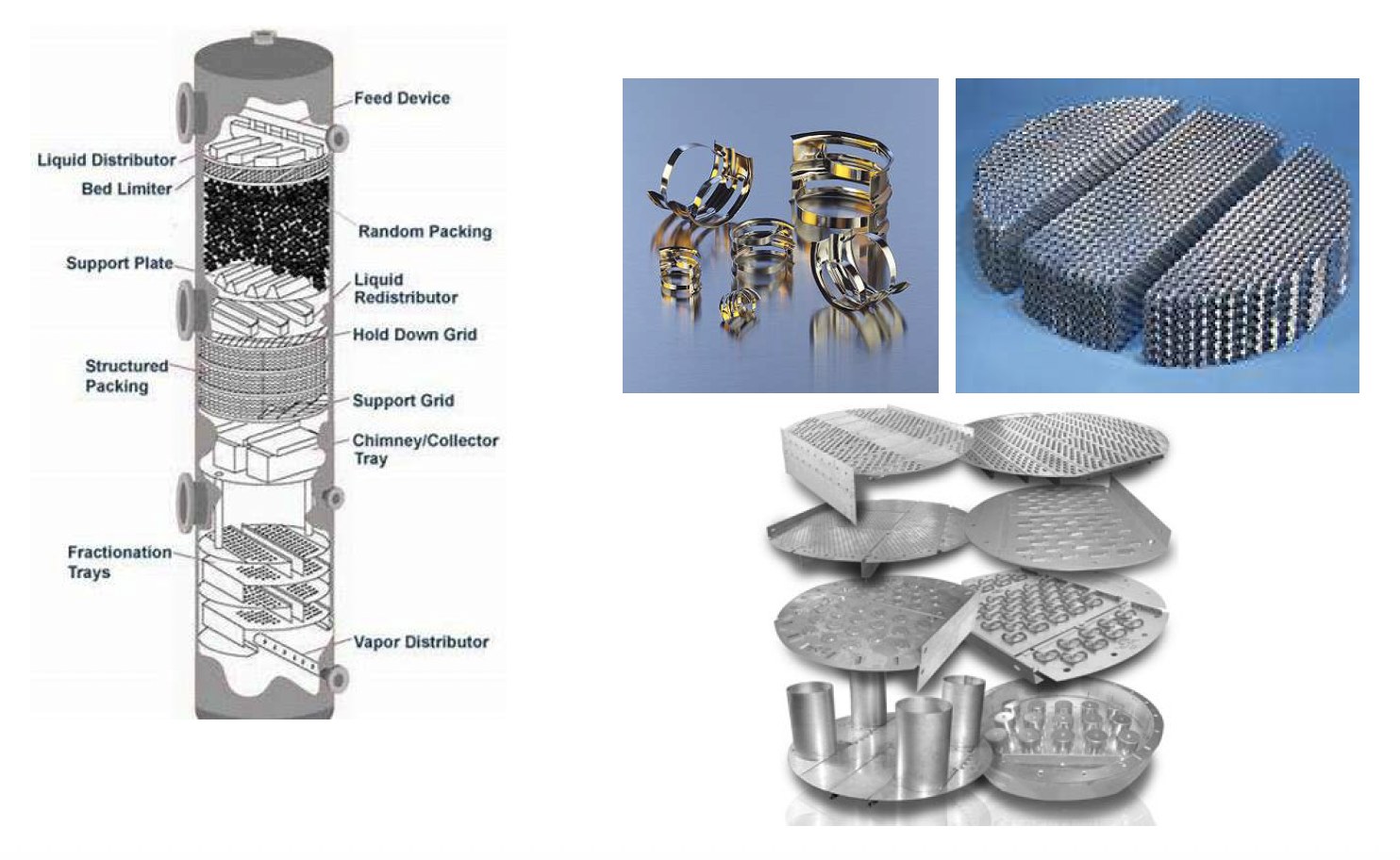

COLUMN INTERNALS (Mass Transfer Solutions)

Column performance is not driven by process conditions alone—the internals package is often the deciding factor. Together with DELION, GEMAGROUP provides complete mass transfer solutions for columns used in distillation, absorption, stripping and related separation duties. Our objective is to deliver stable hydraulics, high separation efficiency, and reliable capacity, supporting both new columns and revamp/debottlenecking projects.

Column performance is not driven by process conditions alone—the internals package is often the deciding factor. Together with DELION, GEMAGROUP provides complete mass transfer solutions for columns used in distillation, absorption, stripping and related separation duties. Our objective is to deliver stable hydraulics, high separation efficiency, and reliable capacity, supporting both new columns and revamp/debottlenecking projects.

Every service has its own constraints: vacuum vs. pressure operation, turndown requirements, foaming tendency, fouling/coking risk, liquid/vapor load range, and operational flexibility. That is why we follow an engineering-led approach: we first define the limitation (flooding/entrainment, excessive pressure drop, poor efficiency, maldistribution, instability, etc.), then build a tailored internals package—combining trays/packings/distributors and supporting internals—to meet the required performance targets.

What we deliver

-

Trays: sieve, valve and high-capacity tray options, engineered for throughput, efficiency and stable operation

-

Packings: full portfolio of structured and random packings designed for low pressure drop, high efficiency and wide operating windows

-

Distributors / Collectors / Supports: liquid distributors, collectors, support grids and engineered internals—because distribution quality is critical to separation performance

-

Revamp & Debottlenecking: practical upgrades to increase capacity, reduce ΔP, improve product quality and stabilize operation—often with minimal downtime

-

Applications: refinery atmospheric & vacuum towers, petrochemical separations columns, chemical services, air separation, and absorption/desorption duties

Outcome-driven: higher capacity or smaller column size, improved product specs, reduced pressure drop, broader operating range, and long-term reliability.

ENERGY AND PETROCHEMICAL TECHNOLOGIES / SERVICES

Integrated Technology Solutions and Licenses

Commercially and Environmentally Superior Technologies

For the successful realization of new gas and petrochemical projects, the selection, validation, integration, and licensing of technologie are paramount. These factors serve as the cornerstone of project success.

Particularly, all commercial aspects must be meticulously considered. We specialize in representing cutting-edge technologies that enhance efficiency while promoting greener and more sustainable processes.

Beyond technology assessments, we deliver tangible results through comprehensive feasibility studies, business case evaluations, and fully integrated skid-mounted process units or modular plants.

Our organization collaborates with internationally recognized and highly experienced teams with a proven track record in refineries and the petrochemical sector worldwide.

Furthermore, we offer dedicated project management for large-scale project execution. Our contractual framework enables us to introduce, oversee, and coordinate EPC (Engineering, Procurement, and Construction) and EPCF (Engineering, Procurement, Construction, and Financing) projects in partnership with globally renowned, industry-leading organizations.

CATALYST BUSINESS

The Heart and Driving Force of Every Petrochemical Facility

The Heart and Driving Force of Every Petrochemical Facility

High-Performance, Long-Lasting Catalysts

For Nearly All Key Processes

The core driver of a stable, efficient, and reliable petrochemical facility lies in the quality and performance of its catalysts.

Delion has secured an exclusive global agreement for a range of highly advanced catalysts, produced in a state-of-the-art facility by an industry-leading manufacturer. These catalysts are custom-engineered to meet the specific requirements of your applications and are delivered directly to your plant.

Our Catalyst Portfolio Includes:

-

Major reforming catalysts

-

Hydrotreating catalysts for diesel and kerosene

-

Dehydrogenation catalysts

-

Other critical, high-performance catalysts

Recognizing that changing a catalyst supplier is a matter of trust and proven performance, we provide comprehensive implementation and commissioning support, backed by extensive references and performance data.

Our expert team is available on-site, worldwide, ensuring a seamless transition and optimized operations. Additionally, we offer competitive pricing and tailored solutions to meet your specific needs, while offering a more sustainable product range.