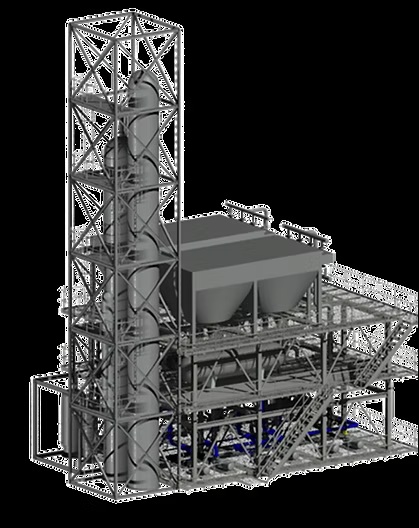

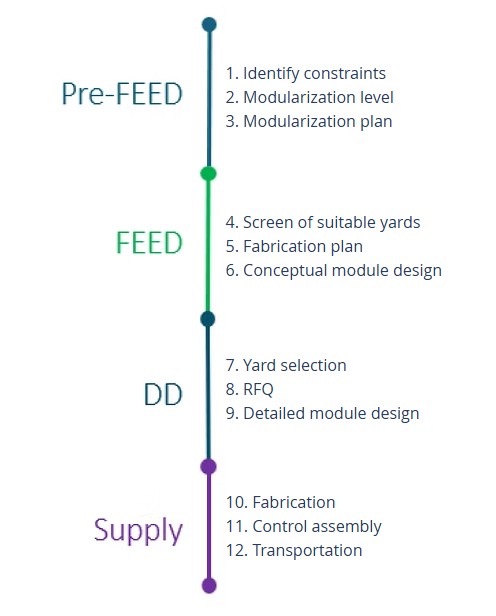

Modularization helps to mitigate the schedule delay and the construction risks through reduction of site manhours. Our expertise and know-how cover all aspects of modularization from design to onsite integration. We assist our clients in defining the strategy that best fits their project needs, offering extensive experience in working with yards.

Modular design for improvements in time efficiency, cost savings, and reliability.

Building on our experience in engineering and operation, we can convert your technology to the modular plants to meet your today’s challenges. These plants provide the best solution for our clients’ varied needs, offering:

Quick time-to-solution achieved through extensive prefabrication and pre-testing.

Streamlined on-site logistics and reduced CAPEX due to modular design.

Expedited equipment fabrication and delivery.

Cutting-edge technology and design for dependable operation.

Simplified maintenance for reduced OPEX.

Comprehensive support services, from consulting to commissioning and start-up.

Confidence assured by our strong commitment to and proven excellence in quality, health, safety, and environmental (QHSE) protection. Download Databook

Modularization advantages:

1. Construction:

Requirement of skilled /costly manpower on site will be reduced

Mitigate harsh climatic conditions

Controlled fabrication environment

Limit interfaces

Reduce site congestion

Reduced construction team

2. Reduced site cost:

Construction manhours

Flatten peak manpower

construction equipment

Site supervision

Decreased camp size and other associated facilities.

3. Quality:

Reliable QHSE management

Higher and better controlled productivity

Easier monitoring of progress and work fronts

Module precommissioning